Vacuum Induction Melting Inert Gas Atomization

Our History

Consarc’s first atomizing furnace was installed in 1969 and is still producing powder today. Our customers draw upon our vast experience delivering over 100 Vacuum Induction Melting Furnaces of 500 pounds and larger worldwide over the past 55 years to the most demanding industries.

Features

Additive Manufacturing:

Products: Fuel Nozzles, Turbine Blades, Aerospace

Alloys: CoCr, IN718 , Mar M 247

Superalloy Powder Metallurgy:

Product: Turbine Disks

Alloys: IN706, IN718, Waspaloy, René 88DT, René 95

Metal Injection Molding:

Products: Vacuum-Cast Powders of superalloys in next gen turbines

Alloys: IN718

Thermal Spray:

Product: coatings for high temperature A&D applications

Alloys: MCrAlY (where M is Ni and/or Co)

Tech Specs

Consarc VIGA Advantages

- Door Mounted Inductotherm Induction Furnaces

- Tandem Tundish System with Dump Pot

- Two (2) tundish doors & one (1) dump pot door with access to atomizing tundish & dump pot

- Induction Heated Tundish

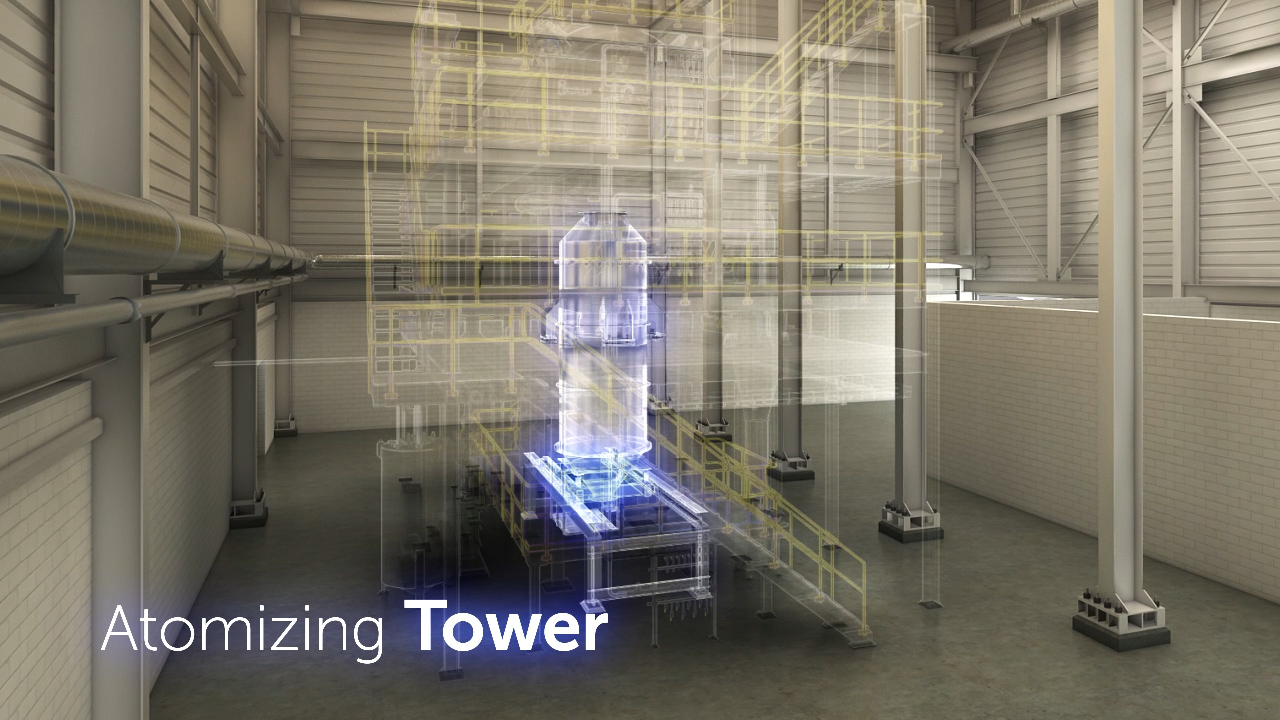

- Vacuum isolation of the melt chamber to the atomization chamber

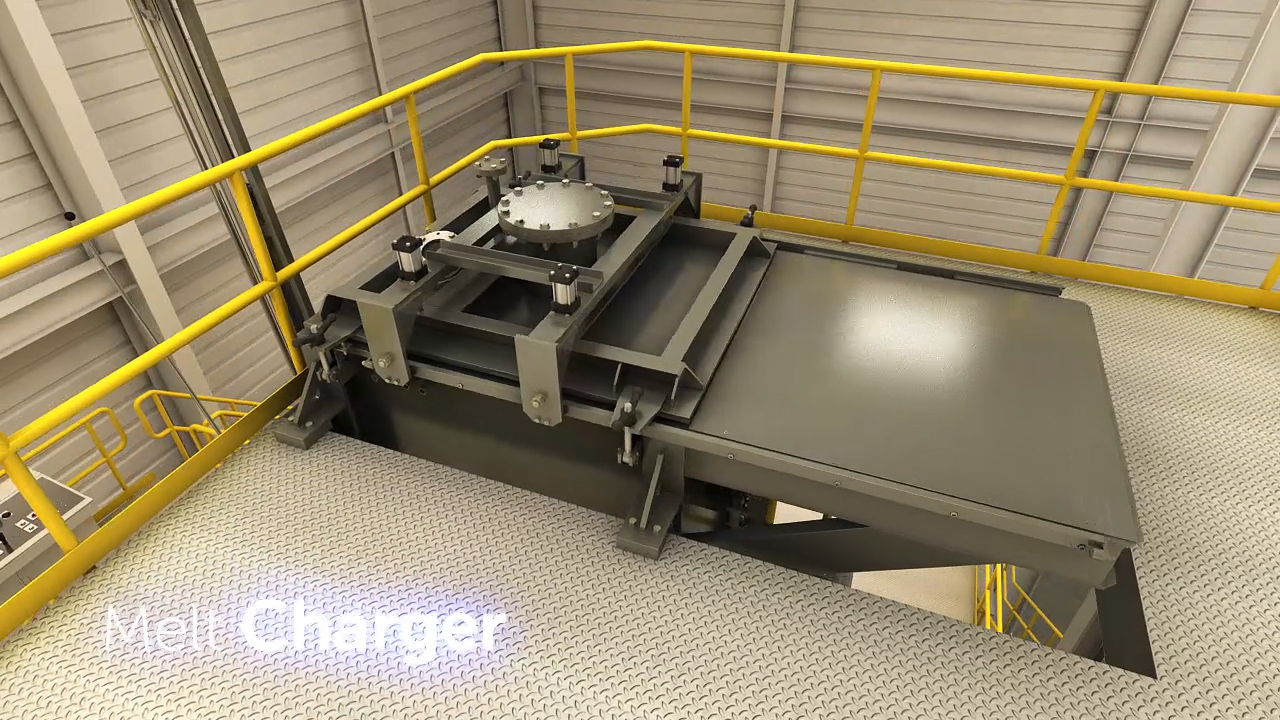

- Overmelt Charger

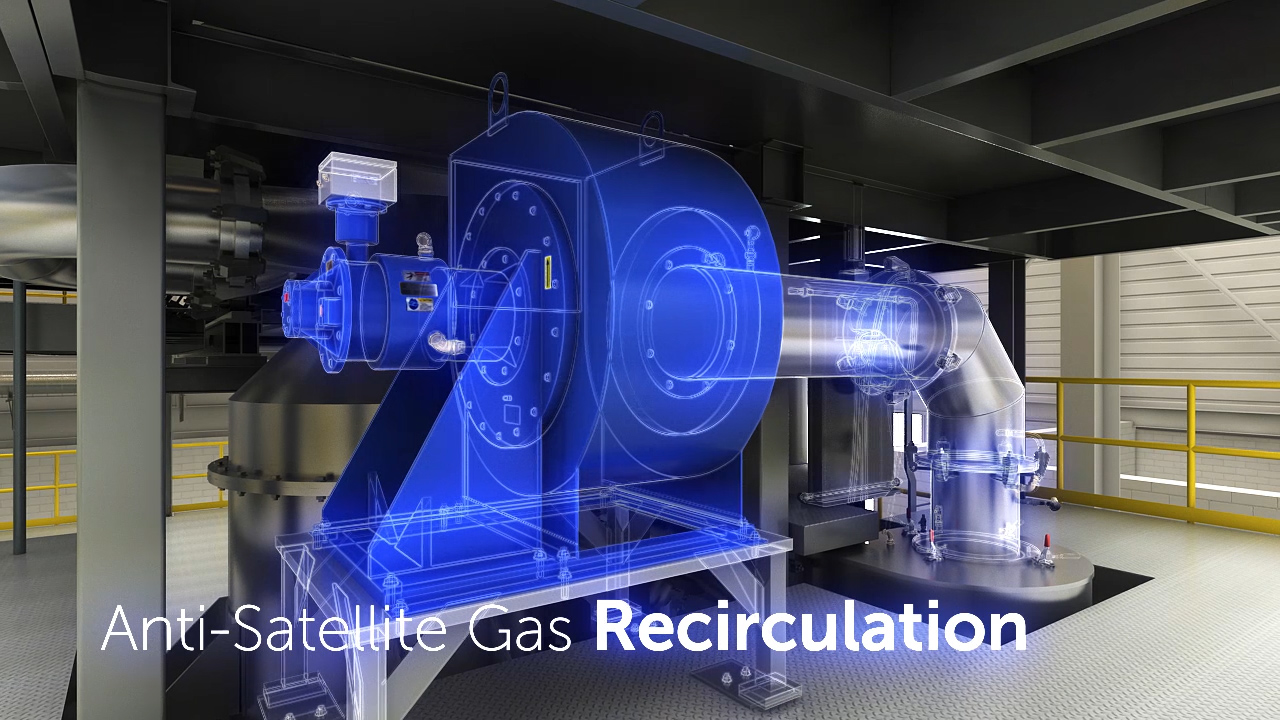

- Anti-Satellite System

- Allows for the most spherical powder shape

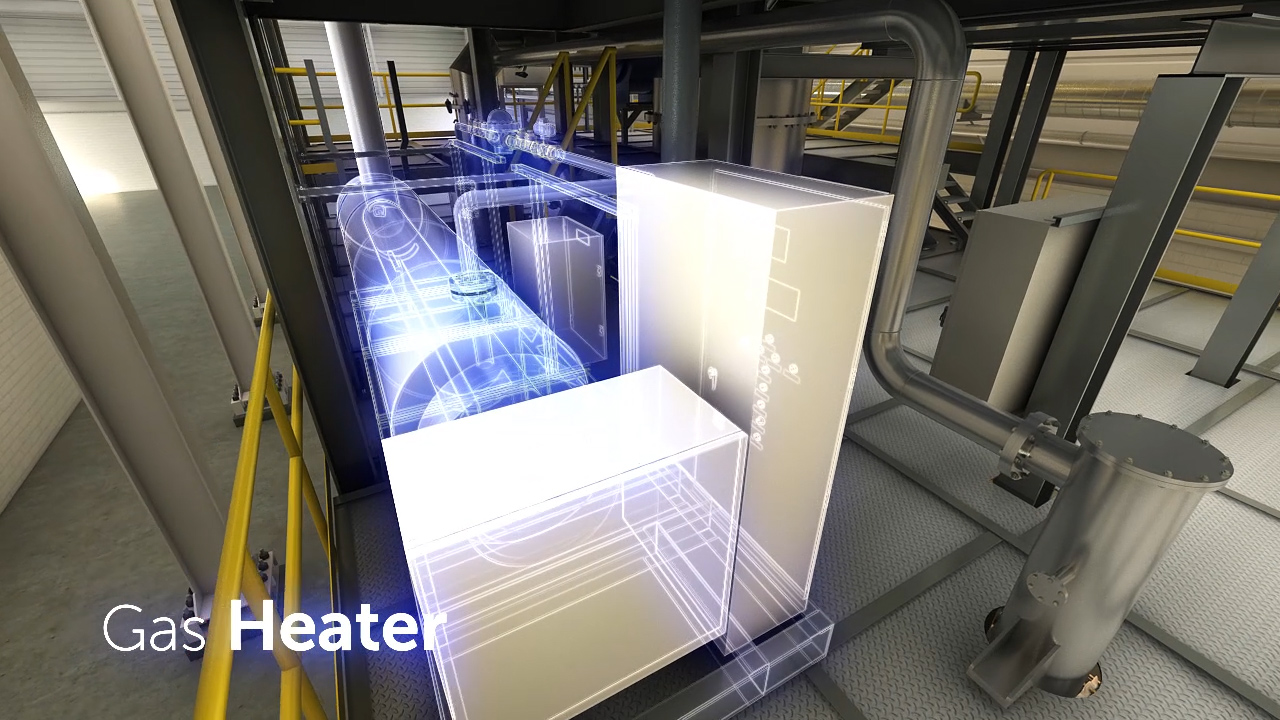

- Hot Gas System

- Allows for Highest Powder Efficiency

- Designed for ease of cleaning when changing melt alloys